Continuous Improvement Philosophy for over 35 years

Our core commitment is continuous process refinement and developing optimal solutions for every technical challenge. Our primary goal is to deliver the best customer experience for rubber composite parts.

Our Competitive Differentiation

We position ourselves as the premier supplier with the best customer experience for rubber composite parts. We distinguish ourselves through technical expertise, continuous improvement and custom solutions beyond conventional capabilities.

Our Technologies

We cover the entire process chain from toolmaking to post-processing. This enables faster production, greater technical refinement, and high reliability.

CNC milling and EDM

Tool manufacturing for rubber production and metal inserts in all quantities.

Injection Molding

Series production of rubber and plastic parts with high repeatability. This method is particularly efficient for medium and large batch sizes.

Learn more

Transfer Molding

Ideal for medium to large series, intricate geometries, and the production of rubber-metal or other composite parts.

Learn more

Compression Molding

Best suited for small to medium series. Ideal for components with lower quantities, higher wall thickness, and composite material requirements.

Learn more

Post Processing

Comprehensive post-processing for flawless components, such as cryogenic deflashing, post-curing, etc.: burr free surfaces, enhanced material properties, and improved durability.

Our History

Elastomer specialists since 1990 – and always in motion.

Company founded by Lorenz Kotter

Relocation to our own facility in Ostermünchen and certification to DIN EN ISO 9001

Installation of the first cryogenic deflashing systems

Digitization and automation of business processes

Acquisition of the first injection molding machine (previously compression press equipment only)

Installation of the first CNC machining center for in-house metal insert fabrication

DIN EN ISO 14001 certification

Leadership transition to Marius Maier and Michael Obermeyer

Certified Quality Systems and Corporate Responsibility

Our operational processes are audited, documented, and certified. This approach ensures that every component, every shipment, and every workflow maintains not only technical excellence, but regulatory compliance.

Our certifications at a glance:

DIN EN ISO 9001 - Quality management

Standardized processes, reliable workflows, and documented quality assurance at each stage of production. - Download Certificate

DIN EN ISO 14001 - Environmental management

Focus on sustainability: resource-efficient production and systematic energy and emissions management protocols. – Download Certificate

Career Opportunities at GUME GmbH

- Ownership and room for ideas

- Exciting roles across manufacturing, engineering, and administrative functions

- Secure employment in a growing company

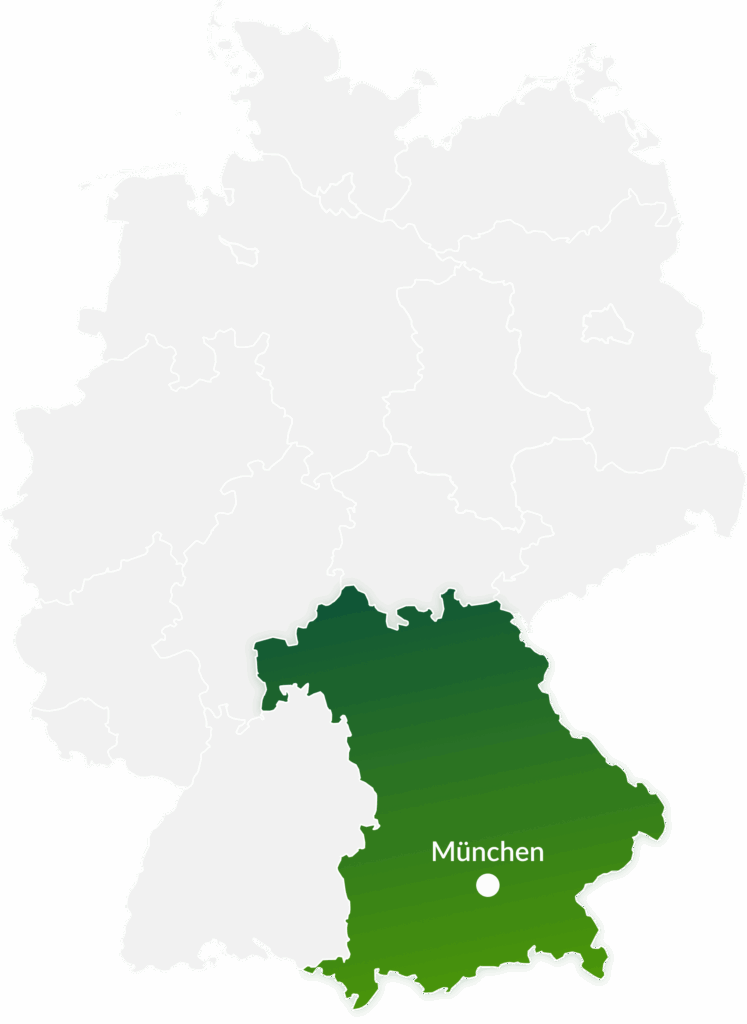

Molded Rubber Parts manufactured in Bavaria

Ostermünchen

Values embodied throughout our Process and Deliverables.

Customer Focus

Our customers remain our primary focus. We deliver solutions that generate tangible value - fast, reliable, and with exceptional quality.

Responsibility

We assume full responsibility for our commitments and the manufactured components we provide to our customers. We take initiative, act proactively, and strive for the best results.

Transparency

We establish trust through clear communication - internally and with our customers. Open communication and a culture of constructive feedback form the foundation of our collaborative approach.

Continuous Improvement Philosophy

We challenge the status quo, identify optimization opportunities, and drive continuous improvement – in technical aspects, organizational structures, and individual competencies.

The GUMEㅤ leadership team

Smart Manufacturing: We combine production expertise with a resilient supply chain

- 100% delivery performance with a resilient supply chain

- End-to-end responsibility from toolmaking and initial sampling to stable series production

- GUME as your proactive, reliable, and transparent partner