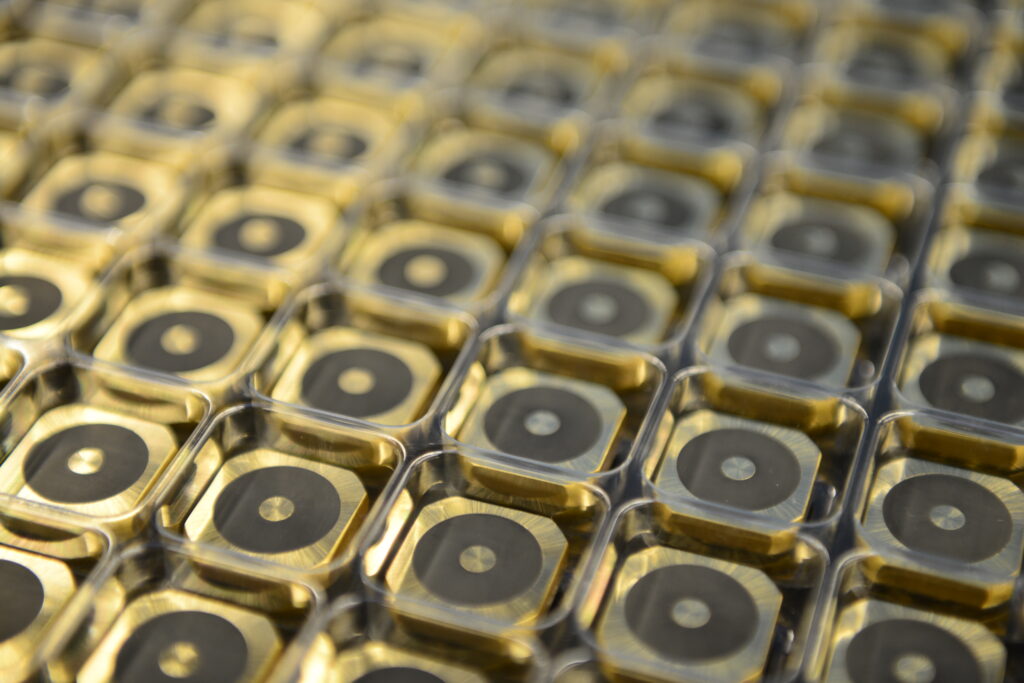

Rubber-Metal Composite Parts – unified stability and flexibility

Performance characteristics and properties

Rubber-metal composite parts unite the advantages of hard and soft components in a single component. Rubber provides flexibility and damping, while metal offers stability and load capacity. The permanent, inseparable bond creates highly functional components with extended service life.

At a glance:

- Superior mechanical stability through metal carrier parts

- Elastic properties for damping, sealing, and vibration isolation

- High load capacity and long service life

- Permanent, inseparable rubber-to-metal bond

- Reduced number of components and reduced assembly effort

- Optimized load distribution through engineered component geometry

Available Materials

We process virtually all standard materials for our rubber-metal composite parts. We combine rubber with various metals and tailor material selection to your requirements.

Metals

Steel, stainless steel, aluminum, brass, and other metallic materials and special alloys - processed and surface-treated in-house for optimal adhesion and high reliability.

Elastomers

NR, EPDM, SBR, NBR, HNBR, CR, FKM, FFKM, and numerous other elastomer compounds, ranging from standard grades to high-performance rubbers with special properties.

Typical Components

- Stop buffers

- Sealing pistons

- Seals

- Flange gaskets

- Rubber‑metal buffers

- Rubber dampers

- Piston rings

- Bearings and bearing pins

- Membranes

- Valves

- Vibration dampers

- Radical shaft seals

Do you have questions?

We have answers!

What performance advantages do metal composite parts offer compared to non-bonded elastomer parts?

Which metals can be incorporated?

We process steel, stainless steel, aluminum, brass, etc. Specialized alloys can be utilized as required. Selection is based on load parameters, weight constraints, and corrosion requirements.