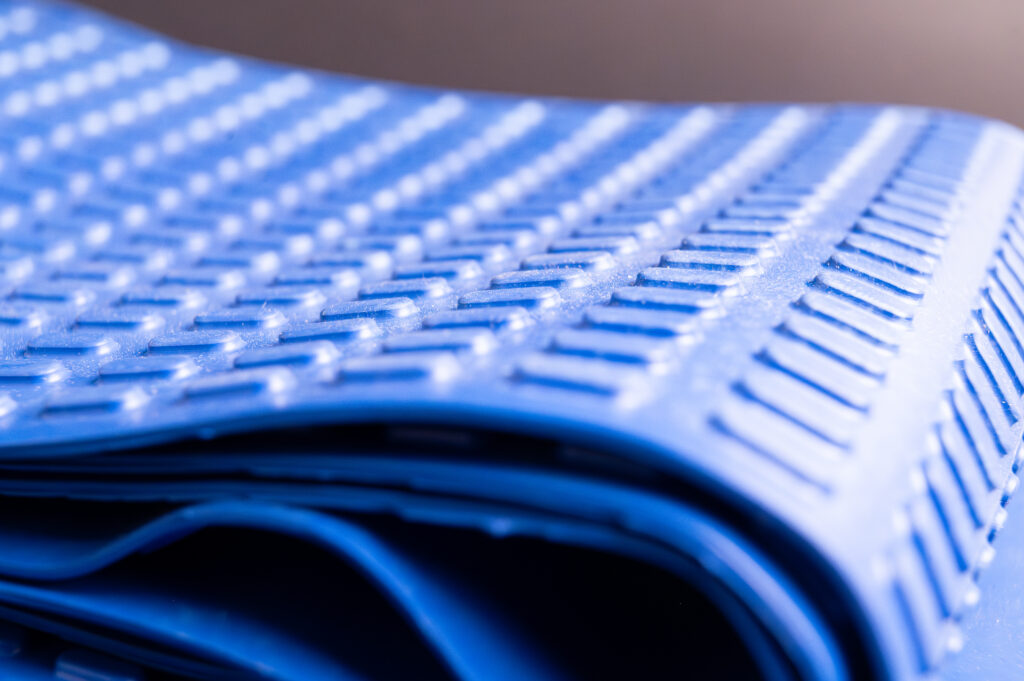

Fabric-reinforced Elastomer Components – for high-load applications and controlled deformation characteristics.

Performance characteristics and properties

Textile-reinforced rubber parts comprise a combination of elastomer compounds and a woven carrier material. The textile reinforcement is embedded within the component or co-vulcanized with the elastomer. The textile structure serves a specific functional purpose: it constrains deformation, stabilizes defined zones, or enhances mechanical strength, while preserving the elastomer's inherent flexibility.

At a glance:

- Minimal weight

- Superior tear strength and tear‑propagation resistance

- Directionally-controlled elasticity

- Enhanced elastic recovery under cyclic loading

- Dimensional stability across temperature gradients

- No delamination through integrated reinforcement

Available Materials

Textile reinforcements are bonded with elastomers during the manufacturing process of molded parts. The result is a permanent bond in which the properties of both materials complement each other for targeted performance.

Glass‑fiber textiles for high modulus and temperature stability

Polyamide and polyester textiles for optimized tear strength and flexibility

Aramid textiles for extreme mechanical loading conditions

Cotton textiles for less demanding applications requiring dimensional stability

Typical Components

- Components for power transmission, bearings, or service conduits

- Seals and membranes with controlled deformation

- Bellows

- Flexible cuffs with enhanced recovery properties

- Components with anisotropic mechanical properties

- Protective sleeves