SILICONE & ELASTOMER COMPONENTS FOR MEDICAL TECHNOLOGY

Over 35 years of experience

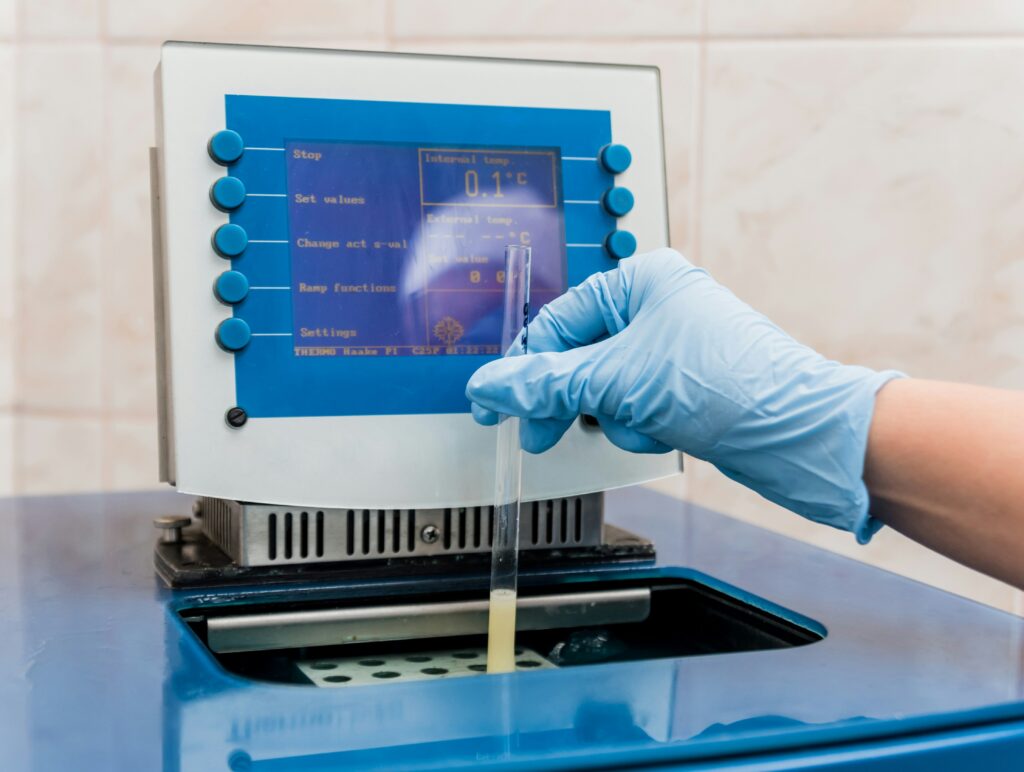

Microscopically precise, macroscopically safe

Biocompatible and FDA-compliant components

Qualified materials for implementation in medical devices and direct patient contact applications.

Multi-sterilization resistance

Repeated sterilization cycles without property degradation enable multiple-use applications and validated reprocessing protocols.

Traceability and documentation

Complete batch identification and regulatory documentation from raw material to finished component.

100% visual and functional verification

Optical inspection and mechanical testing are available for individual component verification when required.

Customer Projects in the Medical Technology

Vulcanized Sheet Metal Profiles for MRIs

Learn more

Motor and Vibration Dampers

Learn more

Rubber Plastic Membranes

Learn more

Medical Silicone Balloons

Learn more

Ultrasonically Welded Plastic Housings

Learn more

Certified Quality Systems and Corporate Responsibility

Our operational processes are audited, documented, and certified. This approach ensures that every component, every shipment, and every workflow maintains not only technical excellence, but regulatory compliance.

Our certifications at a glance:

DIN EN ISO 9001 - Quality management

Standardized processes, reliable workflows, and documented quality assurance at each stage of production.

DIN EN ISO 14001 - Environmental management

Focus on sustainability: resource-efficient production and systematic energy and emissions management protocols.

EN 9100 - Aerospace and defence standard

Meets the highest requirements for reliability, traceability and risk management for critical applications.

ISO 13485 - Medical devices

Ensures biocompatible materials and validated processes for use in medical devices.

Collaborative development: We transform complex design requirements into customized elastomer solutions.

- From material selection to series production - All from a single source

- Personal support from our technical specialists

- In-house tooling capabilities