VMQ - Properties, chemical structure and processing

1. definition VMQ (silicone)

VMQ (vinyl methyl silicone rubber) is a synthetic silicone rubber with high ageing resistance, a wide temperature range from -50 to +210 °C and high flexibility. VMQ material is ozone and UV-resistant, can be made electrically conductive or insulating and is biocompatible. Silicone rubber is therefore frequently used in food technology, medical technology and the pharmaceutical industry - but is also used in high-performance applications in electrical engineering and mechanical engineering, where flexible applications over a wide temperature range are relevant.

History of VMQ

Charles Friedel and James Crafts laid the foundations for organosilane chemistry in 1863, before Frederic Kipping carried out intensive research into organosilicon compounds at the beginning of the 20th century and introduced the term „silicone“ in 1904. Kipping produced silicone oligomers and polymers for the first time, but dismissed them as merely useless chemical curiosities. It was not until the 1960s that the importance of silicones was recognised and further developed. Today, silicone components such as VMQ can be found in a wide range of applications such as highly stressed seals and bearings, in coatings for fabrics, as hoses and as profiles and moulded parts in a variety of machines.

Terminology VMQ (silicone)

The designations VMQ, MVQ, FVMQ and PVMQ all refer to silicone rubber and differ only in terms of the chemical side groups attached.

- VMQ / MVQ: Methyl and vinyl side groups

- FVMQ: additional fluorinated side groups

- PVMQ: additional phenyl-containing side groups

The Q stands for the identical siloxane backbone in all cases. The preceding letters indicate which organic groups are attached. Different properties of the final elastomer can be achieved by varying the attached organic groups, but the basic material class remains unchanged.

Chemical composition of VMQ

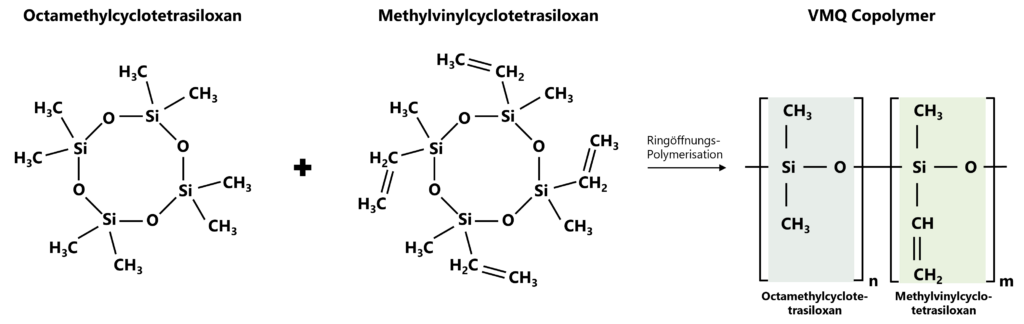

The VMQ elastomer stands out in contrast to other rubbers because it is not a purely organic material. VMQ polymers consist of silicon (Si), oxygen (O), hydrogen (H) and carbon (C) atoms, which are combined by two different monomers to form a so-called copolymer, consisting of 2,2,4,4,6,6,8,8-octamethyl-1,3,5,7,2,4,6,8-tetraoxatetrasiloctane and 2,4,6,8-tetramethyl-2,4,6,8-tetravinyl-1,3,5,7,2,4,6,8-tetraoxatetrasiloctane.

Figure 1: Formation of a VMQ copolymer (right) by ring-opening polymerisation of octamethylcyclotetrasiloxane (left) and methylvinylcyclotetrasiloxane (centre)

These two monomers form the linear polymer chains of the VMQ polymer, which consist of alternating silicon and oxygen atoms (-Si-O-Si-). The attached substituents of the polymer form methyl (-CH3) and vinyl groups (-CH=CH3). Furthermore, fillers and additives in the polymer such as silicic acid influence the mechanical and physical properties such as the hardness of the VMQ elastomer.

2. properties VMQ (silicone)

The properties of VMQ can be categorised into chemical, mechanical and physical properties.

Chemical properties of VMQ

VMQ is chemically very resistant to external influences such as oxidative stress or thermal stress. The typical working range of moulded parts made of VMQ is between -50 °C and +210 °C, which makes VMQ elastomers not only extremely heat-resistant, but also highly resistant in low-temperature applications. VMQ also has excellent ozone and UV resistance, which means that VMQ-based materials are also characterised by their durability in outdoor applications.

At the same time, VMQ shows weaknesses in its chemical resistance to many fuels and to most fats and oils as well as aromatic solvents and ketones. Contact with these media leads to swelling of the VMQ polymer and thus to damage. However, VMQ is stable against many acids and alkalis as long as they are not too concentrated or strongly oxidising.

The BfR-compliant and/or FDA-compliant silicone rubbers are suitable for use in food and medical applications and, thanks to their neutral odour and taste and their physiological harmlessness, are also suitable for applications with food contact or for medical applications with skin contact. For special applications with drinking water contact, drinking water-certified silicone compounds are used that fulfil additional requirements for leaching and extraction behaviour, making VMQ elastomers particularly suitable for use in seals, hoses and fittings with drinking water contact.

Mechanical properties of VMQ

Mechanically, the VMQ elastomer not only exhibits relatively low compression set, but also very good permanent elasticity - especially at higher temperatures. These properties can be controlled by the targeted addition of filler additives so that the behaviour of the VMQ materials, such as hardness, tear resistance and abrasion behaviour, can be specifically designed.

Nevertheless, due to its lower tensile, tear and abrasion resistance than many other elastomers such as EPDM, NBR or FKM, VMQ is only suitable to a limited extent for applications subject to high friction or wear.

This results in different types of VMQ polymers, such as the so-called VMQ 60 with a hardness of around 60 Shore A. The Shore A scale describes the hardness of soft materials and is determined by the resistance to penetration of a standardised, spring-loaded test specimen (pin-shaped). The higher the Shore A value, the harder the material. VMQ elastomers fall into the middle range here, which can be described as remaining soft, but not „rubbery soft“. This degree of hardness can be controlled by the level of additives such as silica. If more filler is added, a higher degree of cross-linking is achieved in the VMQ polymer, which leads to increased rigidity and a harder VMQ polymer (possibly VMQ 70). This individual and versatile control makes materials available in a spectrum ranging from soft-elastic to relatively strong qualities.

Physical properties of VMQ

VMQ is particularly characterised by its variable working temperature range of -50 °C to +210 °C, which can be adjusted even further by adding additives. Over this very wide temperature range, VMQ elastomers exhibit very good insulating properties and stable dielectric properties, enabling them to store energy within an electrical field and thus generate an internal field that counteracts and weakens the external field. This makes moulded parts made of VMQ suitable for insulating components that require a high degree of flexibility, such as cable sheathing and components for high- and low-voltage technology. However, by adding certain additives, silicone can also be made conductive and used in ESD components. In addition to electrical conductivity, thermally conductive silicones and colour-transparent formulations can also be created.

Typical VMQ polymers are not self-igniting, but burn when ignited and usually achieve a flame classification number of UL94 HB („slow-burning“). This can also be optimised by adding additives up to flame-retardant or flame-retardant.

3. processing of VMQ (silicone)

VMQ rubber is produced by anionic ring-opening polymerisation. For this, the cyclic monomers 2,2,4,4,6,6,8,8-octamethyl-1,3,5,7,2,4,6,8-tetraoxatetrasiloctane and 2,4,6,8-tetramethyl-2,4,6,8-tetravinyl-1,3,5,7,2,4,6,8-tetraoxatetrasiloctane are negatively charged under basic conditions and thus form the active polymerisation centre at an oxygen atom. This negatively charged oxygen atom attacks another cyclic monomer and transfers the negative charge to this new polymer chain end, which in turn can react further. This is how the linear polymer chain is formed, consisting of alternating silicon and oxygen atoms (-Si-O-Si-).

Vulcanisation of VMQ

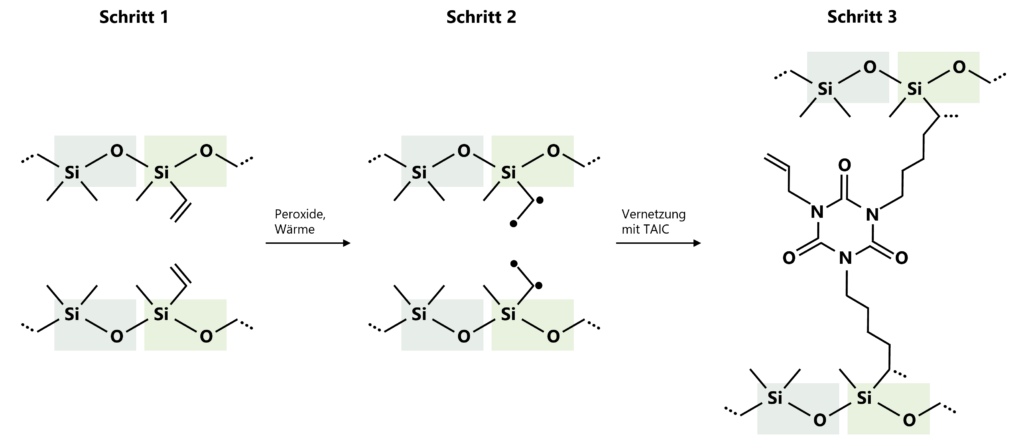

Silicone rubber (VMQ) is typically vulcanised with triallyl isocyanurate (TAIC). At the beginning, the double bonds of the vinyl groups contained in the polymer are broken by peroxides in a radical process, which subsequently creates new carbon-carbon bonds with TAIC. The trifunctional TAIC thus forms a bridge between up to three polymer chains and thus the three-dimensional cross-linking of the polymer. The use of TAIC as a vulcanising agent shortens the curing time of the material and at the same time improves strength as well as abrasion and corrosion resistance.

Figure 2: Vulcanisation of VMQ by breaking the double bonds of the vinyl groups contained in the polymer using peroxides (left) and subsequent crosslinking via triallyl isocyanurates (TAIC) (right).

Technically, VMQ is vulcanised using a moulding process. The VMQ polymer is treated at 150-180 °C in compression or transfer moulding for a few minutes, whereby the conditions vary depending on the mould and wall thickness.

After vulcanisation, VMQ is often post-cured (post-heating), which completes the remaining cross-linking reactions. This improves the mechanical properties and resistance to high temperatures. At the same time, any remaining monomers and volatile components are vaporised by the thermal effect and removed from the VMQ elastomer, minimising outgassing and particle migration. The minimisation of particle migration is particularly relevant for FDA-compliant applications in food technology, pharmaceuticals and medical technology.

Technical processing of VMQ

Technically, VMQ is processed by compression moulding, transfer moulding, injection moulding and extrusion. Different mechanisms and moulds can be used here. HTV and LSR are primarily used for the industrial production of silicone moulded parts:

- RTV silicone (Room Temperature Vulcanising) cures at room temperature. Due to its limited reproducibility and limited mechanical properties, it is rarely used in the production of industrial moulded parts.

- HTV silicone (High Temperature Vulcanizing) is a solid silicone material that is moulded into components at elevated temperatures using processes such as compression moulding, transfer moulding or injection moulding.

- LSR silicone (Liquid Silicone Rubber) is a two-component liquid silicone that is processed by injection moulding. It is characterised by its residue-free reaction and low precision during processing. This makes it ideal for the production of high-purity silicone moulded parts. LSR silicone is particularly suitable for medium and large series, as injection moulding results in higher tool costs and the raw material is supplied in larger material batches.

4. material comparison: VMQ vs. other elastomers

Cost comparison between VMQ and other elastomers

In a cost comparison of different elastomers, VMQ is in the middle of the field between the cheaper TPE/TPU and the slightly more expensive HNBR. In general, the most favourable elastomer materials are made of EPDM or NBR (cost factor x1). These are followed by CR (cost factor x1.2) and PRE/TPU (cost factor x1.3), before VMQ with its LSR variant (cost factor x1.4) and its HTV variant (cost factor 1.8) form the middle price region. More expensive materials with higher performance potential are HNBR (cost factor 2.9) and FKM (cost factor 3.7).

| Material | EPDM | NBR | CR | TPE/TPU | Silicone (LSR) | Silicone (HTV) | HNBR | FKM |

|---|---|---|---|---|---|---|---|---|

| Cost factor | x 1,0 | x 1,0 | x 1,2 | x 1,3 | x 1,4 | x 1,8 | x 2,9 | x 3,7 |

EPDM, NBR, CR and TPE/TPU are cheaper than VMQ polymers, but offer poorer high-temperature, UV and ozone resistance and are therefore preferred for less demanding applications. HNBR and FKM are significantly more expensive than VMQ and are chosen when high oil and fuel resistance (HNBR/FKM) or extreme chemical resistance (FKM) is required.

| International abbreviation | VMQ | FVMQ | EPDM | FKM | |

| Hardness range (in Shore) | 20A-90A | 40A-80A | 20A-95A | 50A-90A | |

| Mechanical properties at room temp. | Tear resistance | 1 | 1 | 3 | 2 |

| Elongation at break | 4 | 2 | 3 | 2 | |

| Rebound Elasticity | 3 | 1 | 3 | 0 | |

| Continue tearing resistance | 1 | 1 | 3 | 1 | |

| Abrasion resistance | 3 | 3 | 1 | 2 | |

| Compression set srest | at max. continuous operating temperature | 0 | 0 | 0 | 0 |

| at room temperature | 0 | 0 | 0 | 1 | |

| Thermal behaviour | Cooling behaviour (Tg) up to °C | -50 | -65 | -50 | -30 |

| Max. Continuous operating temperature up to °C | 220 | 200 | 130 | 220 | |

| Resistance to | Petrol | 2 | 2 | 1 | 3 |

| Mineral oil (at 100 °C) | 2 | 2 | 1 | 3 | |

| Acids (aqueous inorganic acids at RT) | 2 | 2 | 3 | 3 | |

| Alkalis (aqueous inorganic alkalis at RT) | 2 | 2 | 3 | 3 | |

| Water (at 100 °C, distilled) | 2 | 2 | 3 | 3 | |

| Weather and ozone | 3 | 3 | 3 | 3 | |

What distinguishes VMQ from FVMQ?

VMQ has a very wide temperature application range, but has low resistance to oils, fuels and other chemicals. FVMQ is the fluorinated version of VMQ and was developed to significantly improve resistance to media. The temperature range remains comparable, while FVMQ has higher material costs and is primarily used for media-loaded applications.

What distinguishes VMQ from EPDM?

VMQ is clearly superior to EPDM in the high and low temperature range. EPDM, on the other hand, offers very good resistance to weathering, ozone and ageing at a lower cost. In terms of oil and fuel resistance, both materials are unsuitable. EPDM is the more economical choice if the extended temperature range of VMQ is not required.

What distinguishes VMQ from FKM?

VMQ covers a wider temperature range compared to FKM, but has lower mechanical strength and poor resistance to oil and media. FKM is clearly superior to VMQ in terms of resistance to oils, fuels and chemicals and is mechanically more resilient. However, FKM is significantly more cost-intensive and its low-temperature behaviour is more limited than VMQ.