Assembly Services for Rubber Composite Systems

We assemble complete units from molded rubber parts, composite components, and purchased parts, delivering precise manufacturing, verified quality, and fewer interfaces for your production.

Assembly expertise for your systems:

Complete Assemblies

We produce and assemble individual parts made of rubber, metal, and plastic into functional units.

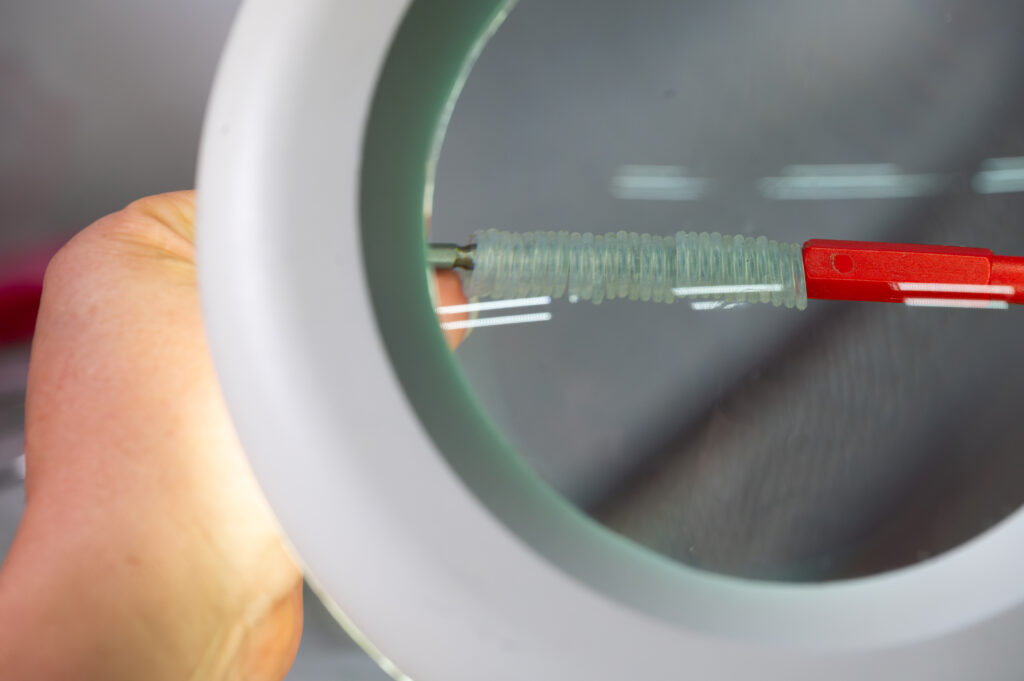

Wide Range of Joining Processes

Our services include processes such as press-fitting, screwing, bonding, and riveting, tailored to your application.

Integration of Purchased Parts

On request, we integrate customer-specified purchased parts with our components, reducing interfaces, and delivering assembly-ready systems from a single source.

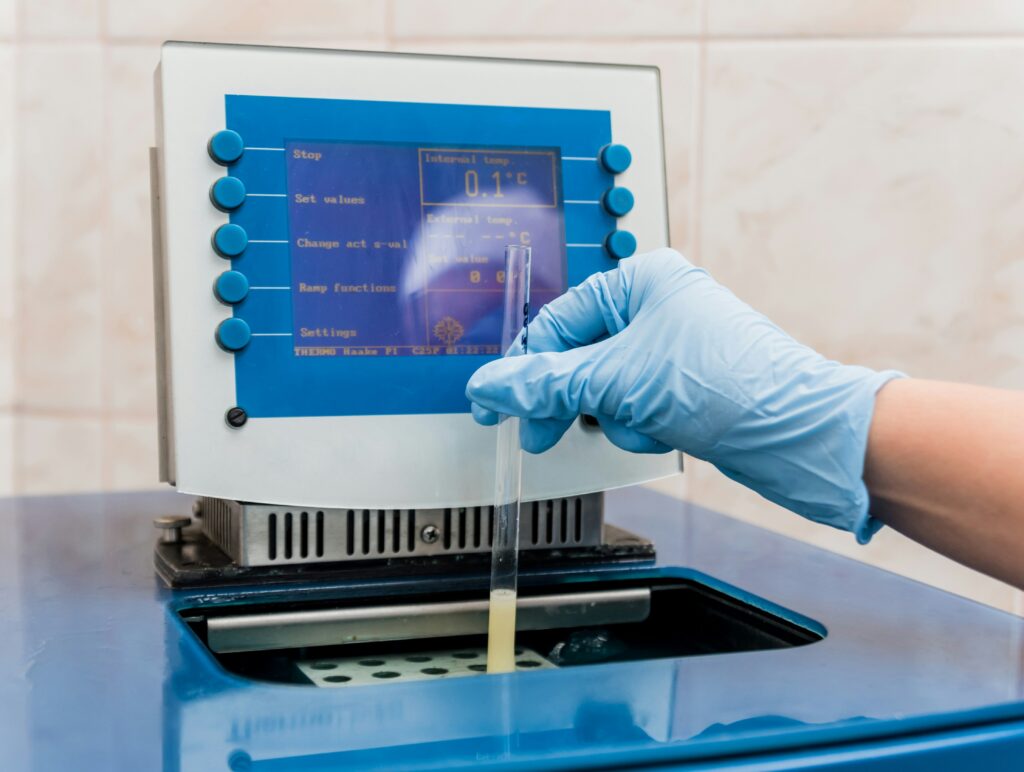

Quality Inspection and Functional Testing

Every assembly is inspected against defined criteria, from dimensional accuracy and mechanical strength to functionality. All results are documented and fully traceable.

Customer-Specific Packaging and Logistics

We deliver assemblies in your desired configuration: pre-configured, labeled, and on schedule for immediate processing.

Insights into Our Customer Projects

Vulcanized Sheet Metal Profiles for MRIs

Learn more

Rubber Metal Quick Clamping Device

Learn more

Motor and Vibration Dampers

Learn more

Do you have questions?

We have answers!

What advantages does assembly offer?

Which joining processes do you use?

Can purchased parts also be integrated?

How is the quality of the assemblies ensured?

What quantities can be realized?

Can assemblies be packaged and labeled to customer specifications?

Smooth Production: Fewer interfaces. Greater reliability.

- Production and assembly from a single source

- Reduced complexity, risks, and coordination effort

- More flexibility and speed with a partner who sees the whole system.