HIGH-PERFORMANCE ELASTOMER COMPONENTS FOR Mechanical Engineering

Over 35 years of experience

In Mechanical Engineering, downtime is not an option

Superior chemical and thermal resistance

Elastomer components must be capable of withstanding temperature ranges from -40°C to +200°C and beyond, while resisting aggressive chemical exposure, hydraulic fluids, lubricating compounds, and coolants, all while maintaining elasticity without swelling, abrasion, or crack formation.

Mechanical durability

Continuous vibration, cyclic compression loading, and frictional wear require highly abrasion-resistant elastomers with demonstrated fatigue resistance through millions of operational cycles.

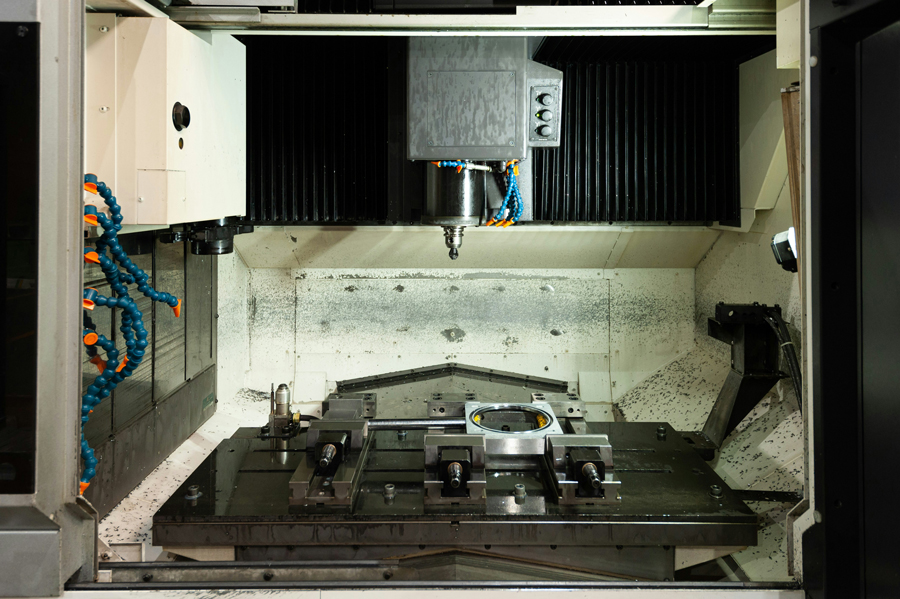

Micrometer precision

Precise manufacturing to nominal dimensions and maintenance of tight tolerances is essential for optimal functionality and simplified assembly integration.

Custom geometries

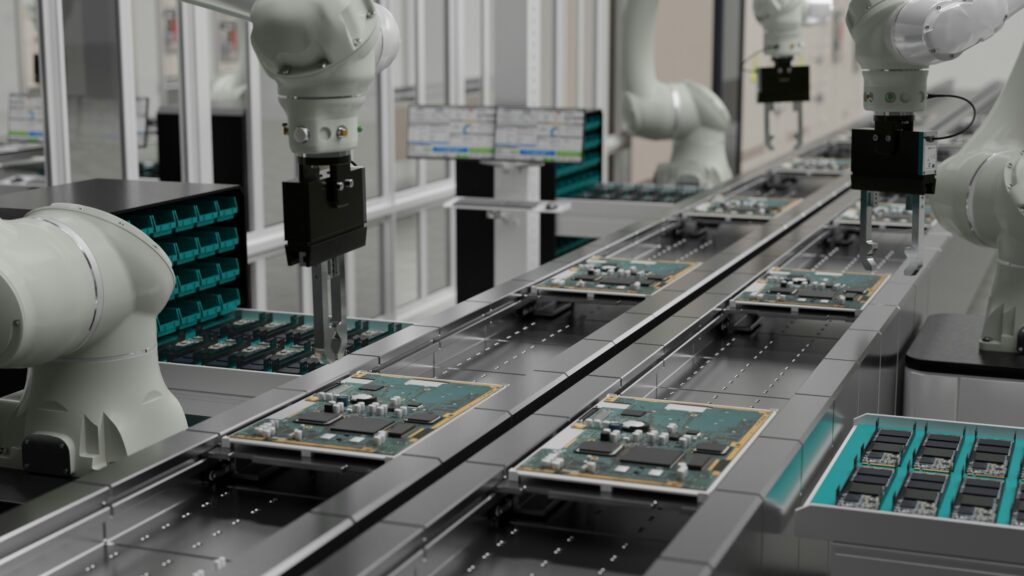

Standard catalog components rarely provide optimal solutions. We manufacture elastomer components economically and precisely engineered to your design specifications, even for low-volume production.

Customer Projects in Mechanical Engineering

Miniature Silicone and Rubber Suction Cups

Learn more

Housing Covers with Integrated Seal

Learn more

Bearing Pins and Carriers for the Food Industry

Learn more

Certified Quality Systems and Corporate Responsibility

Our operational processes are audited, documented, and certified. This approach ensures that every component, every shipment, and every workflow maintains not only technical excellence, but regulatory compliance.

Our certifications at a glance:

DIN EN ISO 9001 - Quality management

Standardized processes, reliable workflows, and documented quality assurance at each stage of production.

DIN EN ISO 14001 - Environmental management

Focus on sustainability: resource-efficient production and systematic energy and emissions management protocols.

EN 9100 - Luft-, Raumfahrt- und Verteidigungsstandard

Erfüllt höchste Anforderungen an Zuverlässigkeit, Rückverfolgbarkeit und Risikomanagement für kritische Anwendungen.

ISO 13485 - Medizinprodukte

Gewährleistet biokompatible Materialien und validierte Prozesse für den Einsatz in medizintechnischen Geräten.

Collaborative development: We transform complex design requirements into customized elastomer solutions.

- From material selection to series production - All from a single source

- Personal support from our technical specialists

- In-house tooling capabilities